Maintaining the integrity and functionality of industrial pipelines is paramount for safety, efficiency, and compliance. Pipeline cleaning is a critical part of this process, ensuring that your network functions without the risk of blockages, leaks, or corrosion. However, not all pipeline cleaning is created equal, and there are important guidelines to follow. In this blog post, Winterhawk Pipeline Services in Tulsa, Oklahoma, takes you through the dos and don’ts of pipeline cleaning, empowering you to make informed decisions to safeguard your infrastructure.

The Importance of Proper Pipeline Cleaning

First, understanding why pipeline cleaning is vital will set the stage for the actions you’ll want to take. Unclean pipelines can result in a plethora of issues, from reduced flow efficiency to contaminated products. They can also lead to costly downtime for maintenance and the potential for environmental harm.

Do Recognize the Warning Signs

The ‘do’ list starts with being proactive. Recognizing the signs of a pipeline in need of cleaning can not only save time but also prevent catastrophic events. Look out for things like inconsistent flow rates, increased system pressure, or the need for more frequent equipment maintenance.

Don’t Dwell on Downtime

On the flip side, while recognizing the signs is crucial, allowing these to disrupt your operation is not. Don’t wait until the last minute to clean your pipelines. Preventative action will reduce downtime and ensure the smooth operation of your system.

The Right Way to Clean Pipelines

Pipeline cleaning is both an art and a science. It involves understanding the type of material to be removed and selecting the appropriate method to avoid damage.

Do Choose the Right Method

There are several methods for cleaning pipelines, including mechanical and chemical cleaning. The method you choose should be based on the type of contaminant present, the material of the pipeline, and the diameter of the pipe.

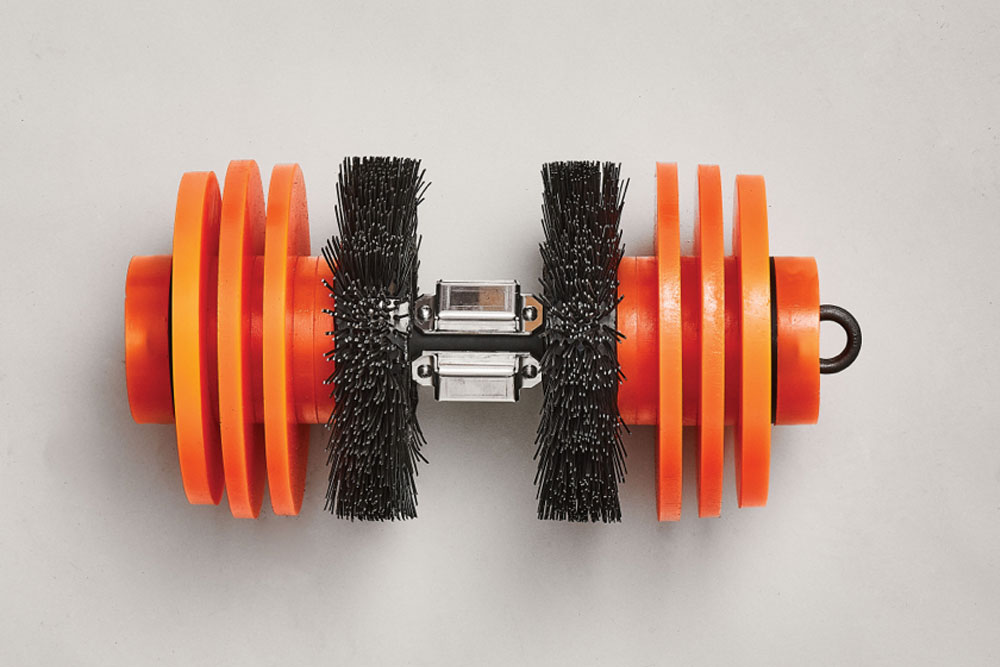

Mechanical Cleaning

Mechanical cleaning uses tools such as pigs or brushes to scrape the inside of the pipe walls. This is ideal for removing solid materials or tough deposits but requires careful consideration of the pig design and material to prevent damage.

Chemical Cleaning

Chemical cleaning involves the use of solvents or acids to dissolve contaminants. This is more effective for removing oily substances, scaling, and soft deposits. However, chemical cleaning requires thorough planning to ensure the safety of personnel and the integrity of the pipeline.

Don’t Neglect Safety

Safety must always come first when cleaning pipelines. Ensure proper training for personnel, use appropriate personal protective equipment, and follow safety protocols to prevent accidents or exposure to hazardous substances.

Environmental Considerations

Pipeline cleaning can have environmental implications, depending on the method and the materials cleaned out.

Do Consider Environmental Impact

Choose your cleaning method with the environment in mind. Mechanical methods can often be more environmentally friendly as they involve the removal and disposal of solids. Chemical cleaning, however, must be carefully managed to prevent the release of hazardous substances into the environment.

Don’t Forget Regulatory Compliance

Ensure that your cleaning activities comply with all relevant environmental regulations. This includes proper disposal of waste and obtaining necessary permits for cleaning activities that may impact the environment.

Maintenance Planning

After your pipeline is cleaned, proper maintenance planning is key to ensuring the effort isn’t wasted and that you have a clear timeline for the next cleaning.

Do Establish a Regular Cleaning Schedule

Establishing a regular cleaning schedule will help you maintain the efficiency and longevity of your pipelines. This schedule should be based on the type of material being transported, the duration of transport, and the sensitivity of the system to build-up.

Don’t Skip Regular Inspections

Even with a cleaning schedule in place, pipelines should be regularly inspected for signs of wear, corrosion, or damage. Inspections can reveal the need for more frequent cleaning or the need for repairs before a failure occurs.

Contact Us Today

Pipeline cleaning is a complex and vital component of pipeline maintenance. By recognizing warning signs, choosing the right cleaning method, considering safety and environmental impacts, and maintaining a regular cleaning schedule, you can contribute to the smooth operation and longevity of your pipelines. Winterhawk Pipeline Services is dedicated to providing expert advice and services to ensure that your pipeline cleaning efforts are effective and sustainable. If you’re in need of further guidance or professional assistance, don’t hesitate to reach out to our team in Tulsa, Oklahoma.