In the complex world of pipeline maintenance and inspection, precision is paramount. For organizations like Winterhawk Pipeline Services based in Tulsa, OK, ensuring the integrity and safe operation of pipelines is not just a duty but a core commitment. This brings us to a crucial tool in the arsenal of pipeline maintenance technology – Pipeline Caliper Tools. These sophisticated instruments are indispensable for assessing the condition of pipelines and ensuring they meet safety standards and regulatory requirements.

The Critical Role of Pipeline Caliper Tools

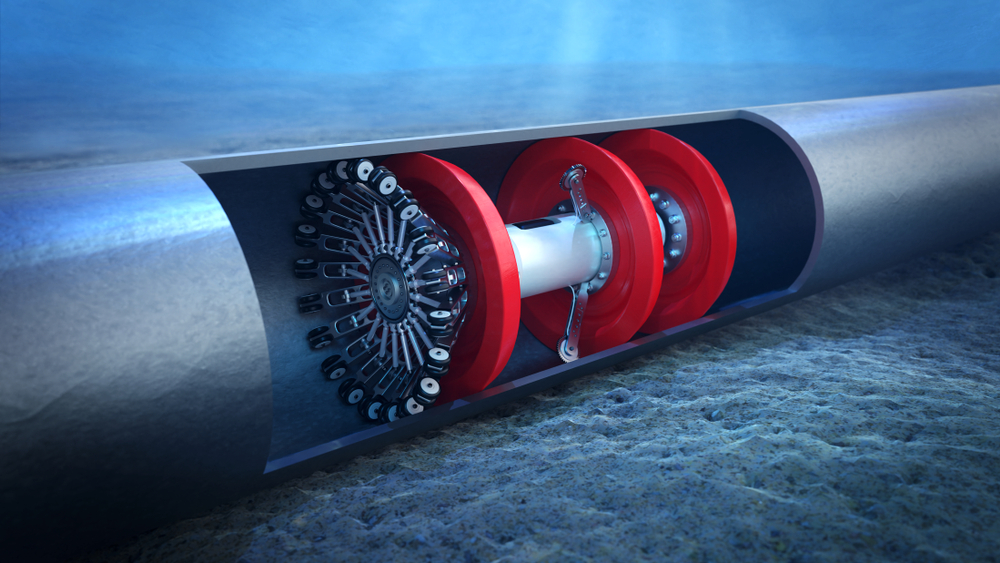

Pipeline Caliper Tools, or pipeline caliper pigs as they are often referred to, play a vital role in the pipeline industry. They are designed to traverse the pipeline, maneuvering through bends, valves, and other pipeline features, to measure the internal conditions and dimensions accurately. This ability makes them essential for detecting anomalies such as corrosion, dents, buckles, and weld defects that could potentially compromise pipeline integrity.

The importance of Pipeline Caliper Tools cannot be overstated. They provide operators with the necessary data to make informed decisions about pipeline maintenance, repair, or replacement, which in turn, helps prevent leaks, spills, and catastrophic failures that could have dire environmental and economic impacts.

How Pipeline Caliper Tools Function

Operating on the basic principle of differential pressure, pipeline caliper pigs are propelled through the pipeline by the product flow itself. They are equipped with multiple arms that extend out to the pipeline walls or tucked underneath the rear cup. As the tool moves along, these calipers slide over the internal surface, measuring distances and detecting irregularities with precision.

Modern Pipeline Caliper Tools are also often integrated with sophisticated electronic systems for data recording. These systems collect detailed information about the pipeline’s internal geometry, which is then analyzed to identify areas of concern. The data collected includes not only dimensional measurements but can also record the location of the identified anomalies through built-in odometers or by using external tracking methods.

Applications and Benefits

The applications of Pipeline Caliper Tools are vast and varied. They are used in both the oil and gas industries for pipelines transporting a wide range of products, including crude oil, natural gas, and refined products. Besides detecting physical abnormalities, these tools are also pivotal in:

- Verifying pipeline construction quality,

- Assisting in the installation of internal pipeline equipment,

- Ensuring compliance with industry standards and regulatory requirements,

- Planning preventative maintenance,

- Enhancing pipeline efficiency and extending its life.

By employing Pipeline Caliper Tools, companies like Winterhawk Pipeline Services can provide their customers with crucial services aimed at maintaining pipeline integrity. The benefits of regular pipeline inspection using these tools are manifold. They help in avoiding costly downtimes, ensuring environmental safety, and ultimately safeguarding public health and safety.

A Commitment to Pipeline Integrity

The use of Pipeline Caliper Tools represents more than just a technical requirement—it’s a reflection of their commitment to excellence in pipeline integrity management. By utilizing state-of-the-art tools like these, Winterhawk ensures that our services not only meet but exceed industry standards.

In the rapidly evolving world of pipeline technology, staying ahead means continually investing in the latest technologies and training. This commitment not only enhances operational efficiency but also provides peace of mind to communities and stakeholders who rely on the safe and uninterrupted operation of these critical infrastructures.

Contact Us

Pipeline Caliper Tools are a testament to the advancements in pipeline inspection technology. Their importance, functionality, and application underscore the industry’s move towards proactive maintenance and safety strategies. For organizations dedicated to upholding the highest standards of pipeline integrity, like Winterhawk Pipeline Services in Tulsa, OK, these tools are invaluable.

In a time when environmental safety and operational reliability are under constant scrutiny, Pipeline Caliper Tools offers a way forward. They represent the blend of technology and commitment needed to ensure the safe, efficient, and economical operation of pipeline systems worldwide.

By adopting and advocating for the use of these advanced tools, Winterhawk Pipeline Services continues to lead the way in pipeline inspection and maintenance, demonstrating a steadfast commitment to the industry’s future and the communities we serve. Contact us today to learn more about our services and how we can help you ensure the integrity of your pipelines.