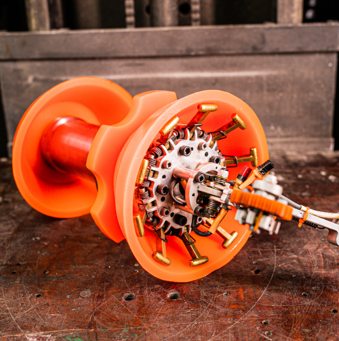

20” DIGI-CAL

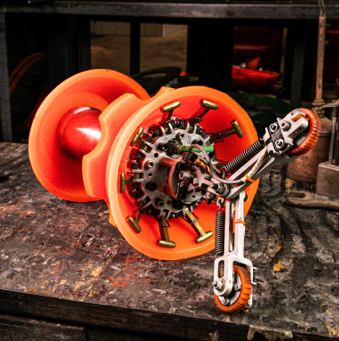

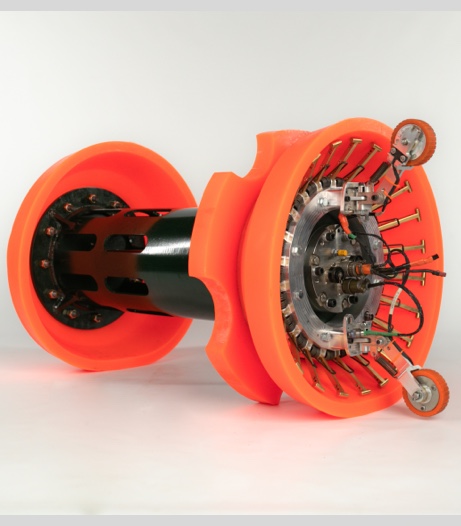

The “Digi-Cal” offers interactive reporting that breaks down all features throughout the line including main line valves, tee’s, bends, pipe wall thickness, welds, and any deformations (anomalies/dents) that have occurred on the line. While using the footage (stationing) from the tool we can also locate and identify line debris.

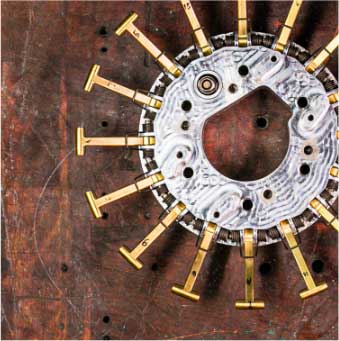

TOOL HIGHLIGHTS

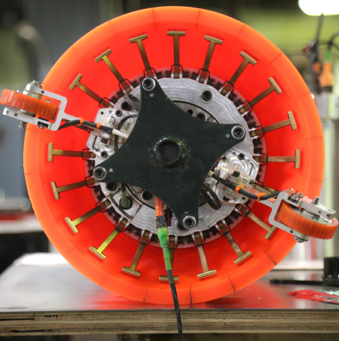

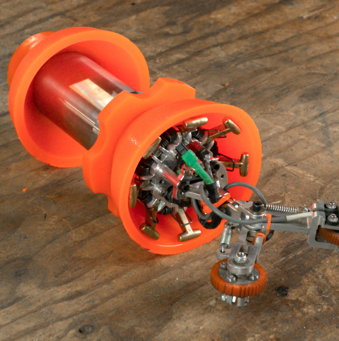

+ NUMBER OF ARMS – 22

+ POWER SUPPLY – 300 hrs +

+ MINIMUM BORE IN STRAIGHT PIPE OF PIPE OD – 27%

+ OPERATING PRESSURE RANGE – 2500 psi or 172 bar

NOTES

+ Approximate pressure range. Consult WPS for operation in low pressure gas lines.

+ Standard configuration.

Electronics engine provides samplings of up to 22 sensors & 44 hall effects.

+ Embedded firmware conserves battery power when unit is idle.

Have any questions?

More Digi-Cal Sizes